Building Leaders from Within

At Via Seating, leadership is cultivated from within through a structured approach to cross-training and tiered advancement opportunities. We believe in empowering our people by building deep, versatile skillsets across our production value streams, creating a strong foundation for long-term growth. Team members are encouraged to develop expertise in multiple roles, allowing them to gain a broader understanding of the full production process while fostering a culture of adaptability and shared ownership. This investment in cross-functional training directly supports our tiered leadership model, which includes value stream leads, seconds (assistant supervisors) and supervisors. Each tier plays a critical role in guiding daily operations, mentoring peers and driving continuous improvement initiatives. By creating clear paths for advancement, we ensure that high-performing individuals are recognized, supported and equipped to step confidently into leadership roles. This dynamic, hands-on development model not only strengthens our teams—it builds a resilient, empowered workforce that’s ready to lead with confidence and purpose.

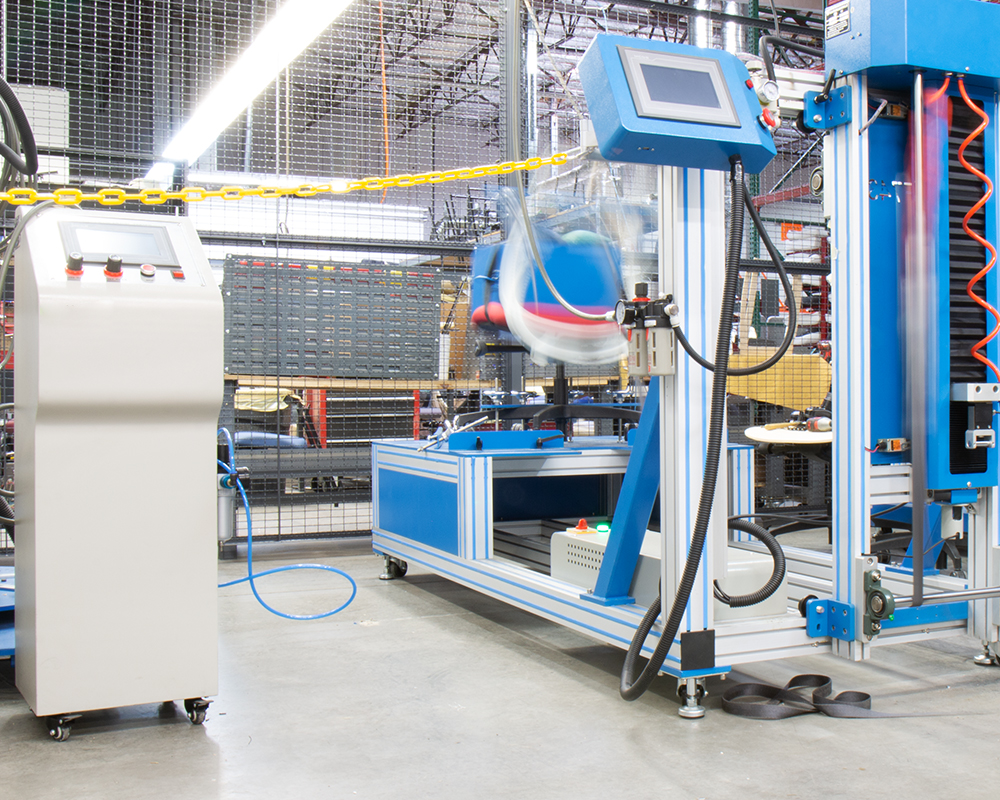

Streamlining Success with Value Streams

Via Seating organizes its production floor into value streams, replacing traditional siloed departments with integrated, end-to-end workflows. This approach aligns teams around a common goal—delivering value to the customer—by streamlining processes, improving communication & eliminating inefficiencies. Each value stream encompasses all the steps required to complete a product, from start to finish, allowing teams to respond faster, reduce handoffs & minimize waste. By focusing on flow rather than function, value streams foster greater accountability, agility & collaboration, ultimately driving higher productivity and product quality.

Kaizen in Action: Cultivating a Culture of Continuous Improvement

Via Seating’s approach to kaizen—the philosophy of continuous, incremental improvement—has been a transformative force across the entire organization. Rooted in lean manufacturing principles, kaizen empowers every team member to actively identify and eliminate waste, no matter how small, and to seek out better ways of doing things each day. This mindset shift has created what we call “lean eyes”—a heightened awareness among employees to spot inefficiencies, streamline processes & enhance value without compromise. Kaizen is not limited to occasional events; it’s embedded into daily operations, team huddles & problem-solving routines, making continuous improvement a living, breathing part of our culture. It encourages collaboration across departments, fuels innovation on the production floor & inspires a proactive attitude that touches every area of the business—from design to delivery. Over time, this disciplined yet empowering approach has made Via Seating more agile, efficient & quality-driven, ensuring that we stay ahead by always getting better.

Solving at the Source: The Power of Five Whys

At Via Seating, the Six Sigma “5 Whys” methodology is a core part of our continuous improvement culture. This simple yet powerful root cause analysis tool helps our teams dig deeper into challenges by asking “Why?” five times, allowing us to move beyond surface-level symptoms and identify the true cause of a problem. By applying this approach across departments—from manufacturing to customer service—we’re able to implement more effective, lasting solutions.

Used alongside our lean manufacturing practices, the “5 Whys” technique empowers every team member to think critically, challenge assumptions & contribute to meaningful process improvements. Whether it’s resolving a production delay or enhancing workflow efficiency, this method ensures we don’t just fix issues temporarily—we solve them at the source.